QINGDAO HONGTAI COPPER TUBE CO.,LTD

Tel: +86 0532-86633071

E-mail: sales@hongtai-copper.com

Address: No. 101, Guiyang Road , Pingdu, Qingdao, China

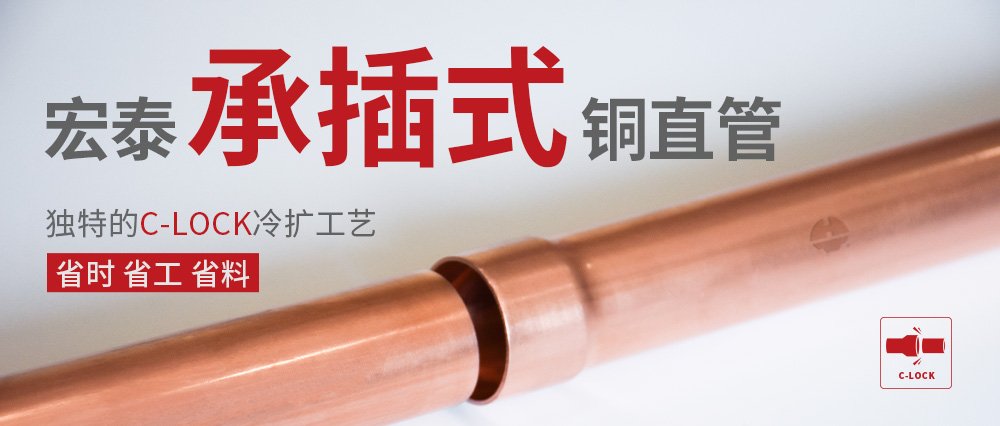

In order to better meet the demands of engineering customers and reduce the construction difficulty and strength, Hongtai has developed a socket type straight copper pipe which is directly flared at the copper pipe end through the cold expansion process. Both ends of the copper pipe are made into sockets and sockets, eliminating manual flares and reducing welds. It not only reduces the construction risk, but also saves time, labor and materials.

Where is "unique"?

Hongtai patented technology

The unique c-lock cold expansion process is adopted for the Hongtai socket type copper straight pipe to eliminate the heating flare of the copper pipe, avoid the grain size change of the copper pipe at the flare, and ensure stable and reliable nozzle quality.

Each meter of copper pipe passes flaw detection

Before leaving the factory, all copper pipes are subjected to strict flaw detection by German DB flaw detection equipment. All unqualified copper pipes are screened and eliminated, and the quality is more stable.

Realize batch supply

The production of automatic equipment is the only manufacturer in China that can realize the stable supply of socket-type copper straight pipes.

Ten years warranty

Hongtai socket-type copper straight pipe is guaranteed for ten years, allowing you to easily install and use it with confidence.

Save time, labor and materials

As we all know, in the whole installation and construction process of copper pipes, welding is the most time-consuming and material consuming. The welding process not only needs to consume connecting pipe fittings, but also consumes a lot of welding rods and nitrogen. The Hongtai socket straight pipe replaces the traditional direct pipe fittings with flares, eliminating the need for manual pipe expansion can save cost, improve construction efficiency and save time, labor and materials.

Reduce construction cost

Expand is used instead of copper fittings to reduce the use of copper pipe connectors during construction; because one welding seam is reduced, the consumption of welding rods and nitrogen is reduced, and the construction cost is greatly reduced.

Improve construction efficiency

Using Hongtai socket copper straight pipe can eliminate manual pipe expansion, reduce welding times, save labor, reduce construction hours, and significantly improve construction efficiency.

Reduce construction risk

Avoid the risk of pipe expansion

Prefabricate flared pipes to reduce the engineering strength and quality risk of pipe expansion during construction.

Reduce the risk of leakage

Due to the reduction of welding times, the probability of copper tube overburning is reduced, thereby greatly reducing the risk of copper tube leakage. The more applications, the lower the risk.

相关产品: >>承插式铜直管-产品中心<< >>医用铜管系列-解决方案<< >>给排水铜管系列-解决方案<<